LOG CABINS

Log Cabins Through History

The construction of a log cabin or prefabricated wooden house is designed as a freestanding, statically stable structure using a prefabrication system. For this, we use a pre-prepared base. The elements of the log cabin, the logs, are stacked to the appropriate floor height (260 cm – standard residential height or a custom height as per the buyer’s request).

After that, we install the inter-floor structure in the form of load-bearing beams. The beams are notched, just like the logs, at the connection points with the cabin walls. Then, the log elements for the upper floor or attic are stacked, depending on the intended use of the building and the buyer’s preference.

At the obtained attic or upper floor height, we install the roof structure using rafters. Over the rafters, we nail tongue-and-groove paneling and place a waterproof PVC membrane. Over this membrane, battens of 30 x 50 mm are installed along the rafters. Between the battens, thermal insulation (mineral wool or compressed polystyrene) is added, and finally, a wooden plank layer is placed. Over this plank layer, we install the final roofing material, which is typically bitumen shingles. If using sheet metal roofing, horizontal battens are nailed to support the metal roofing panels.

Walls

Walls have an indispensable function. There are numerous classifications of walls in construction, and their purpose can vary. In addition to their primary role in supporting the ceiling and roof, their protection against various weather conditions is equally important.

The walls we manufacture are made using the “Quatro” corner joint system, with single or double grooving along the length, depending on the wall thickness. The exterior surface can be either flat or rounded.

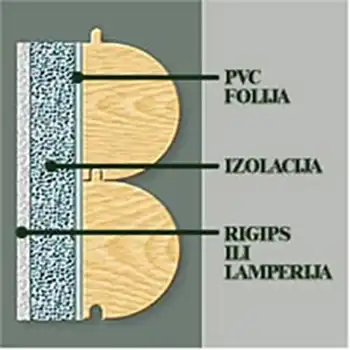

“Sandwich Wall”

Although monoblock walls provide excellent thermal insulation, we also manufacture multiple variations of the “sandwich wall” in the following thicknesses: 25-35 mm, 50-100 mm, and 45-75 mm.

Roof

The roof is an extremely important part of the structure, as the choice and quality of its construction determine the durability of the entire house.

All types of roofing materials available on the market for this purpose can be used: all types of tiles, shingles, onduline, and sheet metal.

Our standard offer includes a 25mm thick wooden plank roofing with waterproofing, on which any of the above-mentioned coverings can be placed.

For optimal insulation, we also offer a “Sandwich Roof” consisting of a layer of wood (2 cm), rock wool or styrofoam (4 cm), an air tunnel (1 cm), and another layer of wood (2 cm). The desired roofing material is then installed on this structure.

Floors

To ensure the durability of the building, a key prerequisite is proper waterproofing at the contact point between the foundation and the initial row of walls and floors. This prevents moisture from spreading from the concrete into the wood.

We manufacture floors from solid wood (20mm thick plank flooring), placing them over a layer of waterproofing and either rock wool or styrofoam (thermal insulation), as illustrated below.

As additional services related to ground floor installation, we offer:

- Adding an OSB board layer (improves thermal insulation)

- Increasing plank flooring thickness from 20mm to 25mm

- Sanding and wood protection treatment

For multi-story structures, we construct inter-floor structures using wood (plank flooring with a thickness of 32mm). Upon customer request, we can create a “sandwich” variant with the following layers (from top to bottom):

- Plank flooring 20-22mm

- Air gap (50mm or more)

- Rock wool for sound and thermal insulation (50 to 100mm)

- Plank flooring 20mm

Additionally, for multi-story buildings, we also manufacture stairs according to the building plan. The steps and supporting side elements are made of wood, with a thickness ranging from 35mm to 50mm, depending on the complexity of the staircase and the mounting method in the structure.

Carpentry

Carpentry, as an essential part of every building, plays a significant role in our production.

Windows

Thermally insulated windows are made of solid wood, featuring double glazing with a 12mm air gap, ensuring optimal insulation – 4mm glass + 12mm air gap + 4mm glass. Glass and metal components are supplied with the structure.

The standard sizes available in our offer are:

- 100×120 cm

- 100×100 cm

- 60×60 cm (for bathrooms)

Additionally, we offer the option to manufacture window shutters, as well as custom-sized windows according to the building plan and client specifications.

Doors

Exterior and interior doors are made of solid wood, with a thickness of 40mm.

Standard dimensions are 80×205 cm and 100×205 cm, but clients can customize the dimensions and door models according to their needs.

We also offer the option of manufacturing balcony doors, available with or without shutters.